What Does Sandblasting And Painting Near Me Mean?

Wiki Article

Sandblasting Machine - Truths

Table of ContentsGetting My Sandblasting To WorkSome Known Incorrect Statements About Sandblasting And Painting See This Report on SandblastingIndicators on Sandblasting Aluminum You Need To KnowOur Sandblasting Alternatives PDFsWhat Does Sandblasting Machine Do?

Likewise called abrasive blasting, sandblasting is a surface ending up procedure that includes the use of a powered equipment commonly an air compressor as well as a sandblasting maker to spray abrasive bits under high pressure against a surface. It's called "sandblasting" because it blasts the surface with fragments of sand.In this message, you'll learn more about this surface finishing process and also just how it's done. Sandblasting leverages the rough residential or commercial properties of sand to create smoother surfaces with less physical flaws and also defects.

When rubbed versus a surface area, the sand removes a few of the top-layer product, thus producing a smoother structure. Sandblasting functions similarly except it entails the use of extremely pressurized sand. The primary step to doing sandblasting is putting the sand right into the sandblasting equipment. Sandblasting makers have a chamber ahead in which the sand is poured.

About Sandblasting

The procedure eliminates several of the excess product on the concrete, which subsequently makes it smoother. Sandblasting is just among a number of blasting-type surface completing processes. There's additionally shot blasting, which is a lot more efficient at smoothing or else harsh as well as inflexible surface areas - sandblasting alternatives. What's the distinction in between sandblasting and shot blowing up exactly? With sandblasting, sand is driven against a surface.

The balls or beads are usually made of stainless steel, copper, aluminum or zinc. Regardless, all of these steels are harder than sand, making shot blasting a lot more efficient than its sandblasting equivalent. No tags for this post.

A Biased View of Sandblasting

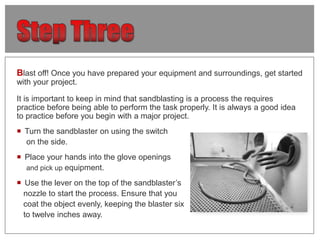

Sandblasting is a terrific method to get rid of corrosion or paint from a product. By using an unpleasant tool and also pressurized air, a sandblaster quickly cleans up a surface area and leaves it fresh. Before start, you need to ensure you pick up the right unpleasant product and understand exactly how to safely utilize a gun.

Not known Facts About Sandblasting Aluminum

Process rates are normally not as quickly as traditional dry rough blowing up when using the equivalent size and kind of media, in component because the visibility of water in between the media as well as the substratum being refined produces a lubricating pillow that can secure both the surface as well as the media, minimizing failure rates.Damp blasting of mild steel will result in prompt or 'flash' corrosion of the blasted steel substrate due to the existence of water. The absence of surface area recontamination likewise permits the usage of single devices for several blasting operationse.

In this procedure pressurized air is included in the water in the nozzle producing a high rate haze, called "vapor". This process is even milder than damp blowing up, permitting breeding surfaces to be cleansed while preserving their capacity to mate. Grain blowing up paint from a concrete aesthetic. sandblasting equipment rental Mixing bits with water substantially decreases dust.

Some Known Factual Statements About Sandblasting And Painting Near Me

In eliminating paint for automobile body work, grain blasting is favored over sand blasting, as sand blowing up has a tendency to develop a higher surface profile than bead blasting.

The size of the wheel blast equipment, and the number as well as power of the wheels differ significantly depending on More about the author the components to be blown up as well as on the expected result and also performance.

9 Simple Techniques For Sandblasting

Either the nozzle or part can be relocated in automated procedure. Automated blasting is just the automation of the unpleasant blowing up procedure. Automated blasting is frequently simply an action in a bigger automated treatment, typically involving other surface therapies such as preparation and coating applications. Care is typically needed to separate the blowing up chamber from mechanical elements that may go through dirt fouling.Tool used for adding sand to the compressed air (top of which read is a sieve for adding the sand) Mobile completely dry rough blast systems are typically powered by a diesel air compressor. The air compressor gives a big quantity of high pressure air to a solitary or several "blast pots".

Report this wiki page